TCC-45 SVO

Pipe diameters: Ø1,5–22 mm | .060” – 0.866”

Pipe material: Copper, Aluminium, Steel, Stainless Steel, CuNi, Brass

Machine type: Industrial machines

Process: Cutting

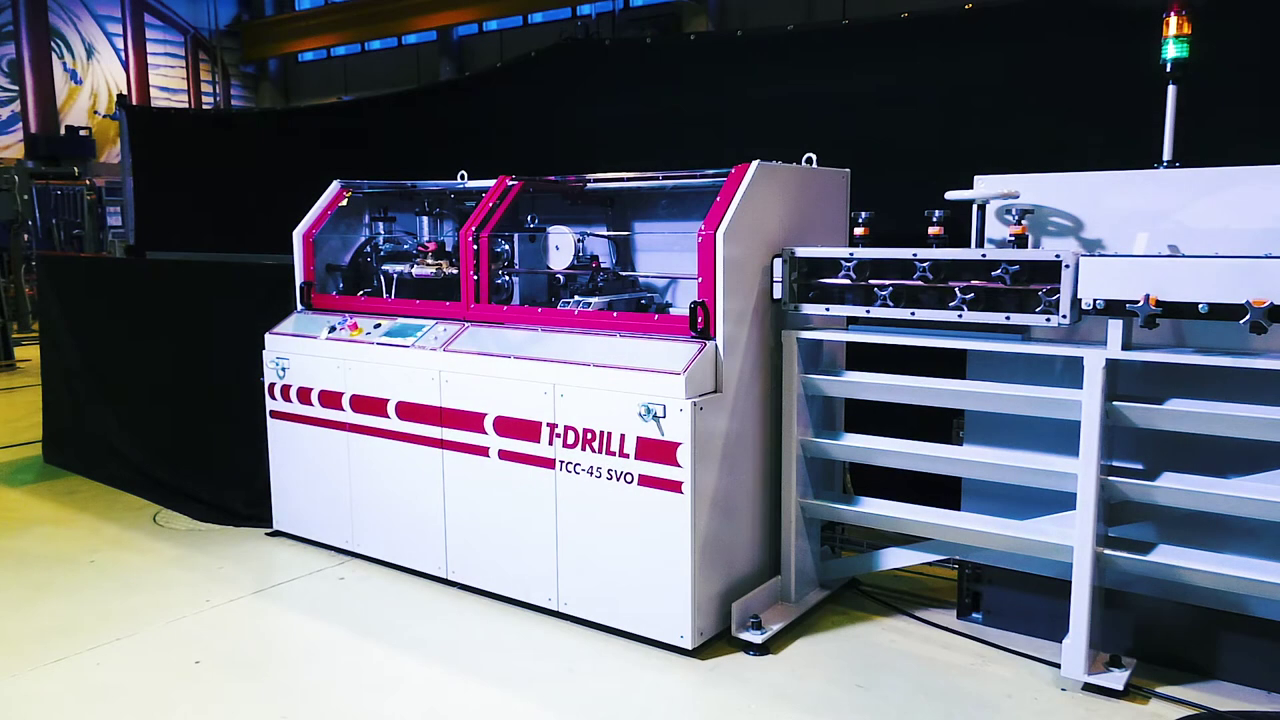

TCC-45 SVO AUTOMATIC ROTARY CUTTING MACHINE WITH SERVO MOTOR BASED FEEDING

The TCC-45 SVO is an Automatic Rotary Tube Cut-off Machine for cutting of all malleable materials such as aluminum, copper, steel and stainless steel. The tube diameters are Ø1,5–Ø22 mm | Ø0.06” – 0.866’’.

The servo-controlled roll feed system enables quick and easy cutting length changes using the touch screen. TCC-45 SVO was designed for applications with cut lengths exceeding 2 m (79’’). It provides a smoother and faster method of feeding longer tube, especially when compared with the standard hitch-feed method. The TCC-45 SVO is typically used for cutting tubes from coil.

The TCC-45 SVO is an energy saving solution and thus an ecological alternative to machines in which tube feeding is powered using compressed air. After cutting, the cut tubes are transferred to a tube collection table that ensures straight run of tubing and allows even roll down to the collection point.

OPTIONS

TCC-45 SVO Cutting Machine

Double Vertical Decoiler

The double vertical decoiler minimizes the coil change over time: When the machine is cutting one coil, the other coil can be changed by the operator.

Horizontal Decoiler

The horizontal decoiler with tension arm or tension unit secures smooth availability for tube feeding.

Tension Arm or Tension Unit

The tension system absorbs jerks exercised on the coil and controls the uncoiling speed. For heavy coils (max weight 1200 kg) there is an electronically controlled tension unit.

Straightening Systems

It is recommended to use a straightener when the tube comes from coil. In our static straightener, precision machined rolls are mounted in two planes and adjusted by the operator to give straight tube. These rolls are specific for each diameter of tube and the straightener is purchased with the number of rolls required by the material. It can also be furnished with a calibration device, which re-rounds any soft tube deformed by the coiling process. Straighteners can be equipped with a pre-straightening device for handling difficult-to-straighten tubes.

Tube Handling Systems After Cutting

Diverting Table for max. 2, 4 or 6 m long cut lengths. The tube diverting table assures straight center line of tube before and after cut-off, allowing even roll down to collection point. This table separates the scrap pieces from the useable parts and sorts good part to three different locations.

The optional tube rewind station is custom built to your specifications. It is available for tube size from 1,5–22 mm and incorporates a defect part elimination system. Parts that pass the eddy current or paint detector are sent to the production end of the machine while bad parts are sent to a scrap area.

TECHNICAL DETAILS

| Maximum tube diameter | Copper, Aluminum: Ø22 mm | 0.866’’ Steel: Ø12,5 mm | 0.5’’ |

| Wall thickness | Copper, Aluminum: 0,4–1,5 mm | 0.02" - 0.06" Steel: 0,4–1 mm | 0.02" - 0.04" |

| Repeatibility accuracy (cutting feed) | ±0.2 mm/1 m |

| Tube materials | Aluminium, Copper, Steel |

| Compressed air supply | 6 bar = 600 kPa |

| Connected power | 6,3 kW |

| Fuses | Max. 3 x 63 A (380–480 V) |

Note! The above values are intended as a guidance only.