Additional Information

Collar sizes: 8–35 mm | NS ½” – 1¼”

Run tube sizes: 15–76 mm | NS ½” – 2½”

Pipe material: Copper, Copper / Nickel

Work cycle time: 20 sec

Machine type: Portable tools

Process: Collaring

The compact and efficient T-35 is designed for the most demanding tube installations. Leading contractors in plumbing, refrigeration and other tube and pipe manufacturing industries have found the T-DRILL T-35 to have all the profit producing capabilities that have been experienced by T-DRILL for decades.

COMPARE YOURSELF!

Click the selected Excel chart below and use your own figures to replace the red ones. The costs by each method will be calculated automatically.

Cost Comparison between Capillary Fittings and T-DRILL Method

Cost Comparison between Press Fittings and T-DRILL Method

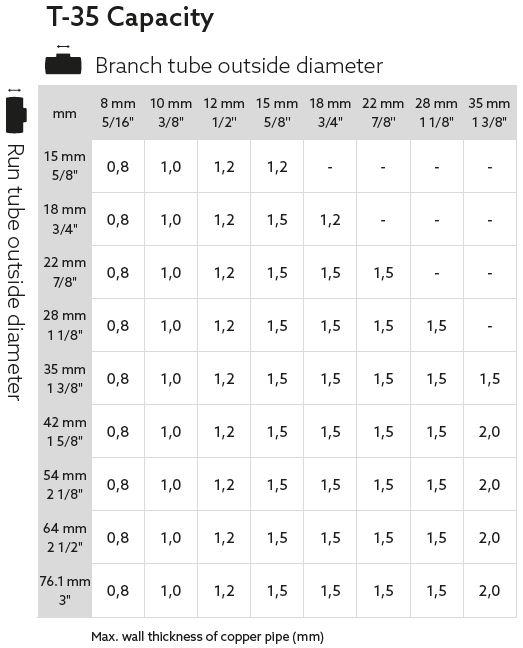

Capacity Chart for Maximum Run Tube Wall Thickness (run tube size on the left and branch size on the top)

Technical Information

| T-35 | Value |

|---|---|

| Collar size | 8–35 mm | NS ½” – 1¼” |

| Run tube size | 15–76 mm | NS ½” – 2½” |

| Max. wall thickness | See capacity chart | K, L, M tubing |

| Material | Copper |

| Cycle time | ~ 20 sec |

| Spindle rotation speed | 0–470 rpm |

| Noice level | 78 dB (A) |

| Vibration | Less than 2,5 m/s2 |

| Dimensions of the unit | 500 x 80 x 200 mm | 19.7'' x 3.1'' x 7.9'' (L x D x H) |

| 4,1 kg | 9,0 lbs | 4,1 kg |

| Supply voltage | 230 V AC/ 50 Hz 110 V AC /50-60 Hz |

Share on social media