CEC-170

Collaring range: Ø19–168,3 mm

Run tube sizes: Ø19–254 mm

Pipe material: Aluminium, Copper, Copper / Nickel, Stainless steel, Steel

Machine type: Industrial machines

Process: Collaring

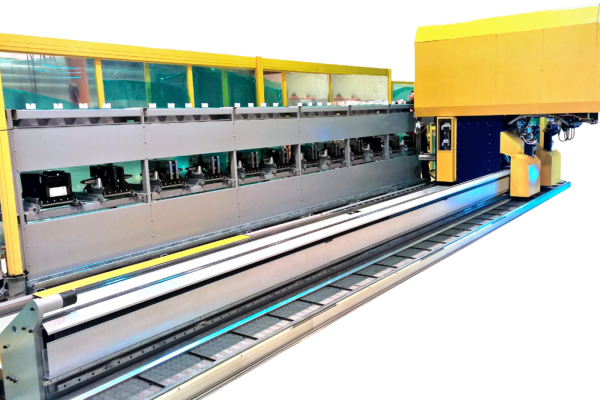

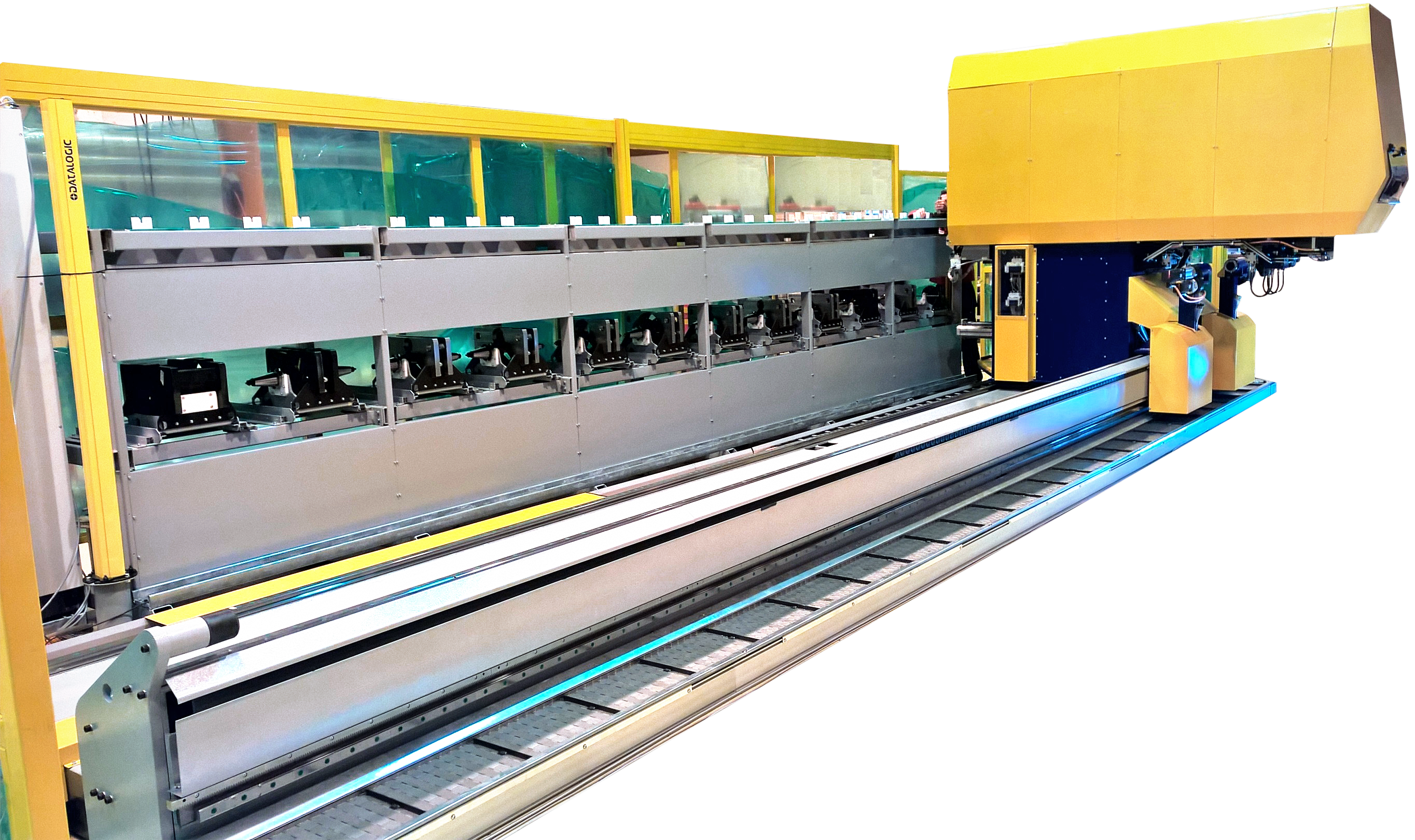

T-DRILL CEC-170 – THE WORLD’S FIRST FULLY AUTOMATIC COLLARING SYSTEM

T-DRILL CEC-170 is a state-of-the-art automatic collaring machine with which productivity can be increased by up to 70–80 %.

Various customized automatic functions can be added to standard ones. This allows fully automatic production of finished workpieces.

The T-DRILL technology used on the machine is based on over 45 years of experience. The solutions have now been upgraded with innovations to meet the targets of 2020’s.

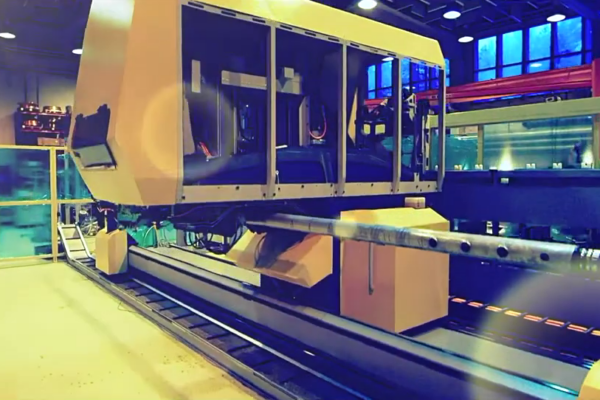

The standard delivery of T-DRILL CEC-170 consists of a high-tech collaring machine and a work piece handling system which includes e.g. one or several Head & Tail pairs. The handling system is always tailored to meet the specific production needs of the customer.

The work piece program is activated either direct from the user interface or remotely from the office. Machine performance, operations and progress of the process are easy to manage and monitor from the user interface.

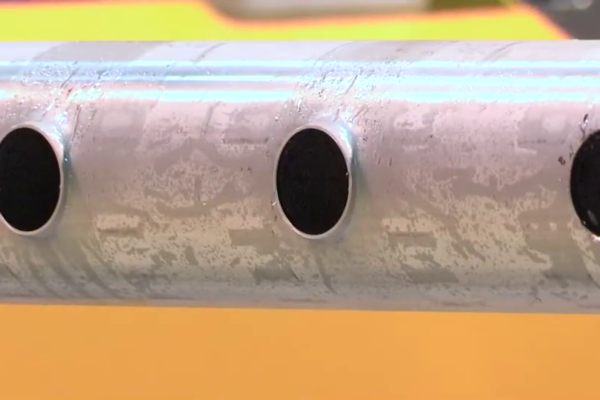

T-DRILL CEC-170 Collaring System has been designed to produce collars between Ø19–Ø168,3 mm for run tubes Ø19–Ø254 mm. The pipes can be loaded automatically by additional loading equipment. The CEC-170 is based on a modular concept, and the basic machine can be extended with several options to a fully automatic cell for producing different size collars to each pipe.

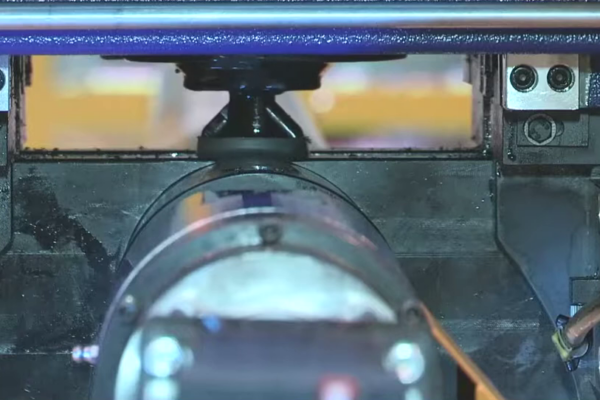

The basic machine includes all functions from pilot hole milling to collaring and trimming. As a standard feature, the machine has a high-speed milling unit with a tool break detector and a tool change system.

The machine is equipped with hydraulic pipe clamps. Changing of tools and pipe specific accessories can be automated using additional options available. The number of tools and range of accessories will be selected to match customer needs.

T-DRILL CEC-170 is a machine of tomorrow. It is available today, yet capable of a flexible response to future needs with the help of pre-designed modular options.