The leading

innovator of

sustainable tube and

pipe fabrication solutions

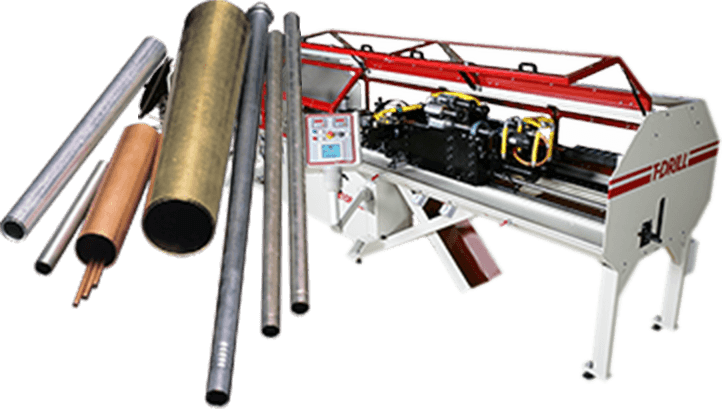

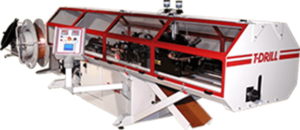

Use T-DRILL technology and achieve new potential in heavy-duty tube end forming and flanging.

Flexible customized tube and pipe fabrication solutions for a vast variety of tubing needs.

Picture a man. He is getting off an airplane somewhere in the world after an 11-hour flight. He grabs his belongings, stretches his limbs and says goodbye to the crew who know him by name. He casually gets off the plane and without batting an eye, hops in a cab, travels to his destination – and gets straight to work. Is he a president? A movie star? No. He is T-DRILL’s Service Engineer Harri Aikio.

FLANGING

- Saves up to 40 % in time and costs, as the flanges are formed directly on the end of the pipe.

- No welding: Fewer points for inspection, fewer weld joints to fail.

- A flange can be produced in 45 seconds cold and about 3 ½ minutes hot.

COLLARING

- No T-fittings.

- No costly inventories.

- Instead of three welded joints, only one simple weld joint is required.

LET’S FIND THE BEST SOLUTIONS FOR YOUR TUBE AND PIPE PROCESSING NEEDS

ONLINE CALCULATOR

Use the calculator to see how much you can save with T-DRILL method.

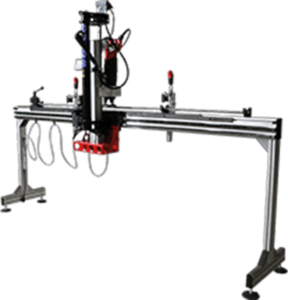

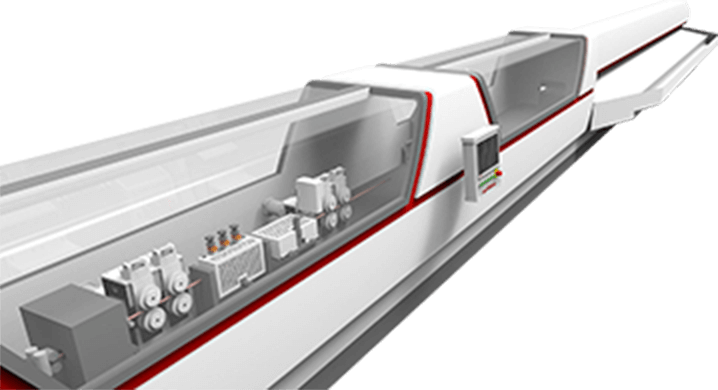

T-DRILL has the capability to create special machinery solutions to meet its customer’s unique manufacturing requirements and to increase their productivity in a highly effective way.

Customized machines. Special machines can utilize already T-DRILL proven technologies such as collaring, chipless cutting, flanging, or tube end forming. This will also give all the benefits of T-DRILL methods with customized machines.

Integrated systems. The modular design of T-DRILL machines and equipment allows us to meet industry-specific requirements and offer optimized tube and pipe manufacturing solutions.